VMC1060B+ column increase cnc metal cutting machine

- group name

- Special Area

- Min Order

- 1 piece

- brand name

- sino cnc machining center

- model

- VMC1060B+

- Nearest port for product export

- shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Wed, 04 Feb 2026 18:03:28 GMT

Paramtents

Numerical control FANUC/SIEMENS/MITSUBISHI

Control method Semi-closed loop control

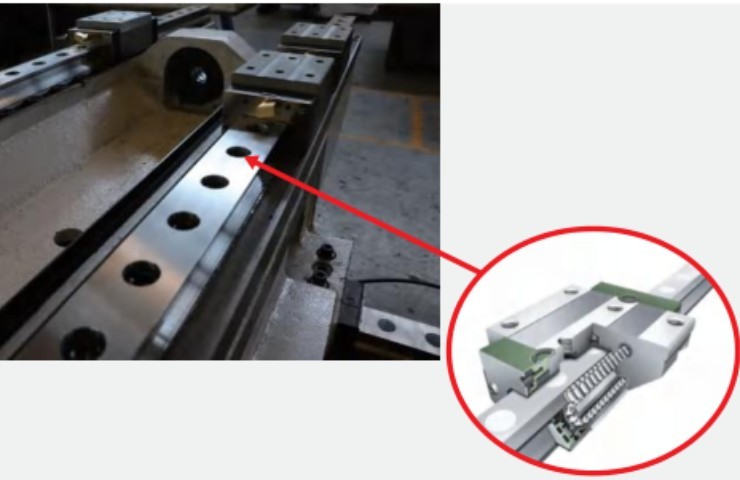

Three axis Roller linear guideway

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Product Introduction

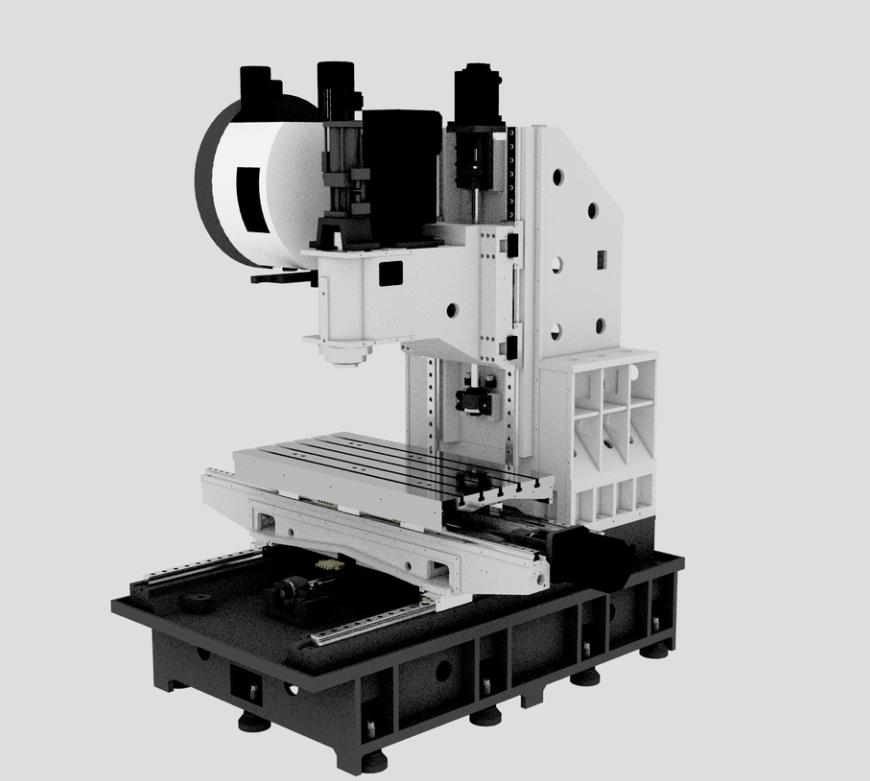

VMC1060B+

Strong Rigidity High productivity Vertical Machining Center

- 40

TAPER

- 3

AXIS

- 8K

RPM

- 24

TOOL CAPACITY

VMC1060B+ Strong Rigidity and High productivity CNC metal cutting machine

B series is featuring high rigidity, heavy cutting ability and high operability. The strong base column construction has optimally-placed ribs to counter chatter and twisting during heavy cutting. With 3 axes roller linear guideway and wide area motor, this vertical machining center can perform heavy cutting and high speed machining with high torque from low to high speed. For this kind special area machine, it is used for auto cylinder head.

Product Detailed Parameters

Machine Model : VMC1060B+

| Table | Value | Unit |

|---|---|---|

| working size | 1200 x 600 | mm |

| Max. load capacity | 800 | kg |

| Travel | Value | Unit |

|---|---|---|

| X travel | 1000 | mm |

| Y travel | 620 | mm |

| Z travel | 600 | mm |

| Spindle | Value | Unit |

|---|---|---|

| Spindle nose taper | BT40 | |

| Spindle speed (pulley) | 8000 opt.10000 | rpm |

| Feed | Value | Unit |

|---|---|---|

| Rapid traverse rate | 36/36/32 | m/min |

| ATC | Value | Unit |

|---|---|---|

| Number of tools | 24 | T |

Product Details Map

Machine Structure:

Wide machine body span and optimum supporting design can meet with fast feed of X and Y axis

Optimum length design of saddle to ensure moving stability of X axis

Big size of “pyramid” column and with closed inner cavity to ensure low center but high rigidity support of Z axis

Column increased 200mm especially designed for auto cylinder head

Spindle :

Taiwan brand short nose BT40-150mm spindle, standard is belt drive 8000rpm. Optional is 10000rpm. 3 bearings in front end and 2 bearings in rear end

11/15Kw spindle wide are motor with high torque 105Nm

Ultralight spindle headstock and Z axis without counter balance block

Tool Magazine :

Shoulder carrying Taiwan brand tool magazine can ensure Z axis geometric accuracy and perfect stability, rigidity and the minimum shock when column loaded with tool magazine weight

Axes Driving :

THK, REXROTH, PMI, HIWIN 3 axes roller type linear motion guideway 35/45/45(X/Y/Z)

By roller linear contacting, the LM guideway can offer a better rigidity which ensure the fast feed rate and reduce cutting time

Physical Picture