HMC800 horizontal machining center

- group name

- One Pallet

- Min Order

- 1 piece

- brand name

- sino cnc machining center

- model

- HMC800

- Nearest port for product export

- shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Wed, 04 Feb 2026 16:06:40 GMT

Paramtents

Numerical control FANUC/SIEMENS/MITSUBISHI

Control method Semi-closed loop control

Three axis Roller linear guideway

Pallet One pallet

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Product Introduction

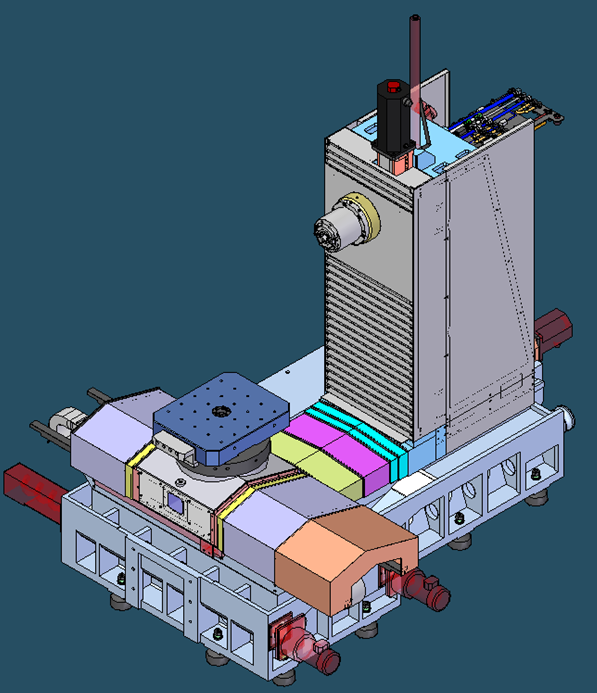

HMC800

Strong Rigidity High productivity Horizontal Machining Center

- 50

TAPER

- 3

AXIS

- 6K

RPM

- 24

TOOL CAPACITY

HMC800 Strong Rigidity and High productivity Horizontal Machining Center

HMC series is featuring high rigidity, heavy cutting ability and high operability. The strong base column construction has optimally-placed ribs to counter chatter and twisting during heavy cutting. With 3 axes roller linear guideway and wide area motor, this vertical machining center can perform heavy cutting and high speed machining with high torque from low to high speed.

Product Detailed Parameters

Machine Model : HMC800

| Table | Value | Unit |

|---|---|---|

| working size | 800 x 800 | mm |

| Max. load capacity | 1200 | kg |

| Travel | Value | Unit |

|---|---|---|

| X travel | 1600 | mm |

| Y travel | 1000 | mm |

| Z travel | 1000 | mm |

| Spindle | Value | Unit |

|---|---|---|

| Spindle nose taper | BT50 | |

| Spindle speed (pulley) | 6000 | rpm |

| Feed | Value | Unit |

|---|---|---|

| Rapid traverse rate | 24/24/24 | m/min |

| ATC | Value | Unit |

|---|---|---|

| Number of tools | 24 | T |

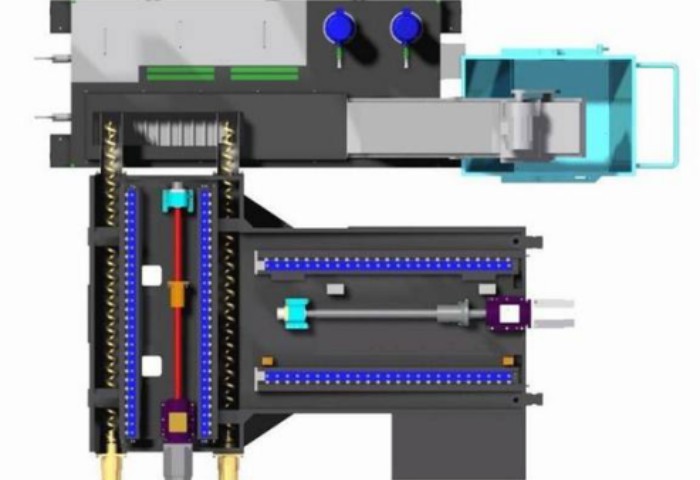

Product Details Map

Machine Structure:

All the machine parts adopted finite element analysis

“M” type cross supporter ,the base weight more than 4000Kg

Spindle :

Standard machine with spindle house oil cooling system to reduce heat distortion during working and keep the stable machining accuracy.

Spindle bearings are three supporter type and six pairs, the dia Φ90mm,high rigidity and rotating accuracy.

Spindle front section with “air window” to protect bearings and increase life span.

Tool Magazine :

Standard: BT50 , 24 position Arm type tool magazine are made by OKADA/POJU who is Professional tool manufacturers in Taiwan.

Optional: Chain type 40T tool magazine.

Axes Driving :

TOP TAIWAN brand Ball screw & linear guideway

Double nuts C3 level grinded ball screws.Screw diameter* pitch: 40*12/40*12/50*12

Roller type linear rails for three axis.The rail size and model: RGW45/RGH45/RGW55.Three axis Slide load block quantity: 4/4/4.

Three Automatic chip conveyors :

Two screw type conveyor to move the chips from inside machine to outside chain type conveyor during working, and the outside chip conveyor transfer the chips to chips tank.

The whole process is smoothly and high efficiency to clean the chips, reduce the machine body heat, escape from machine body heat distortion.

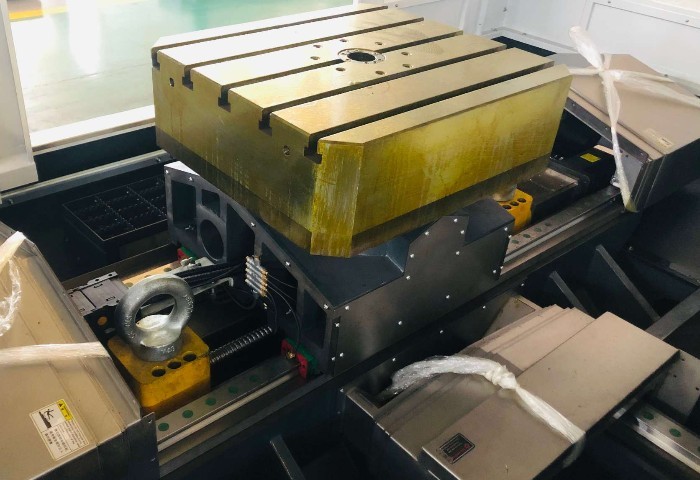

Physical Picture